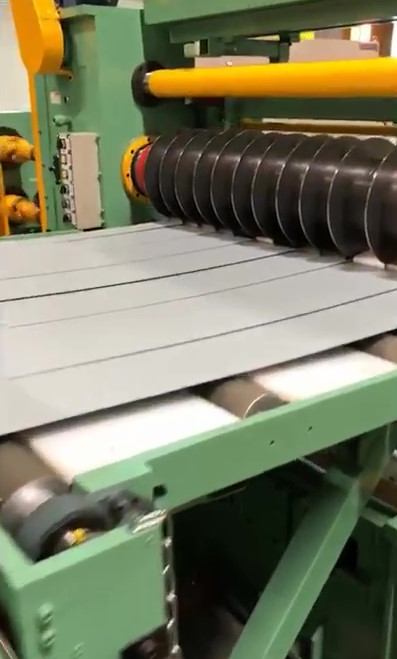

Slitter Line

Slitter line "SM1212"

▷ Width: 1250 mm ▷ Thickness: 0.1 to 1.6 mm

· The tension roll is adopted to a tension device, which makes a good slit processing and winding possible.

· The workload for personnel when changing the blade has been greatly reduced.

· High level Ultra thin coil burr control

SM 1212 film material

Tension roll

The tension roll is controlled by a high horsepower servomotor.

The speed of the tension roll is slightly slower than the speed of the recoiler, which enables the steel strip (coil) to be tightened through braking tension.

The surface of the tension roll is covered with a very thick layer of PU material (50 mm thick on one side). Because this PU material is very soft, it can absorb the speed difference of different steel strips and protect the surface of the steel strip from scratches.

Even if the surface of the tension roll is damaged by burrs, it is still possible to apply tension without damaging the steel strip. Furthermore even if the surface of the tension roll gets deeply damaged, it is possible to continue using the same tension roll by regrinding the surface of the tension roll.

That is why the lifespan of the tension roll is very long and is also longer compared to that of the tension belt.

Comparison table [tension roll ⇔ tension belt]

Tension roll image

Shear Line

Rotary shear "LS 3003"

· It realizes stable shearing and accurate length.

· 6 precision levelers with work rolls enforce a quick shearing.

For the shear motor we use a Japanese low inertia motor.

· Sheared steel strips are quickly received in open storage racks and multiple stocking is possible.